Efficient Drive

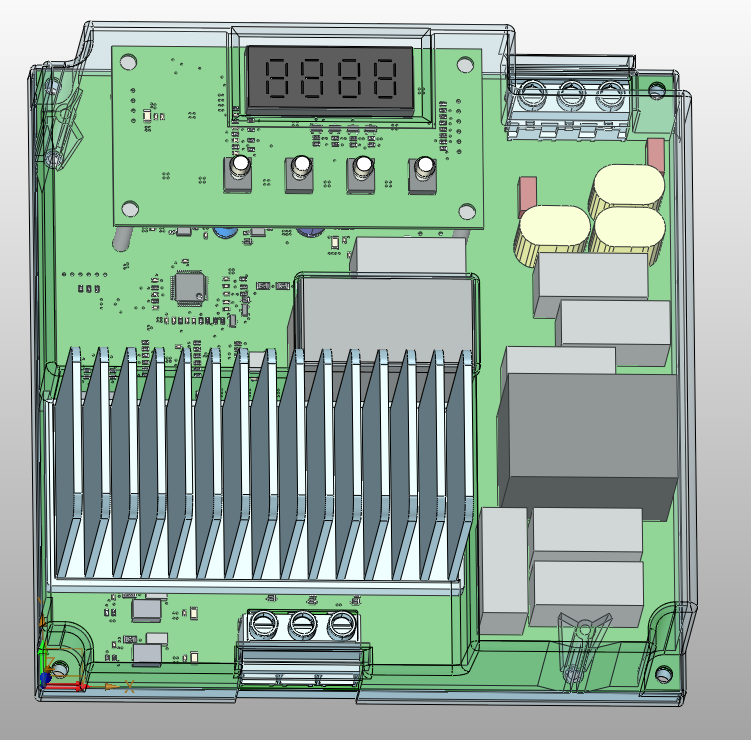

(1) Refrigerator Integrated Inverter Controller:

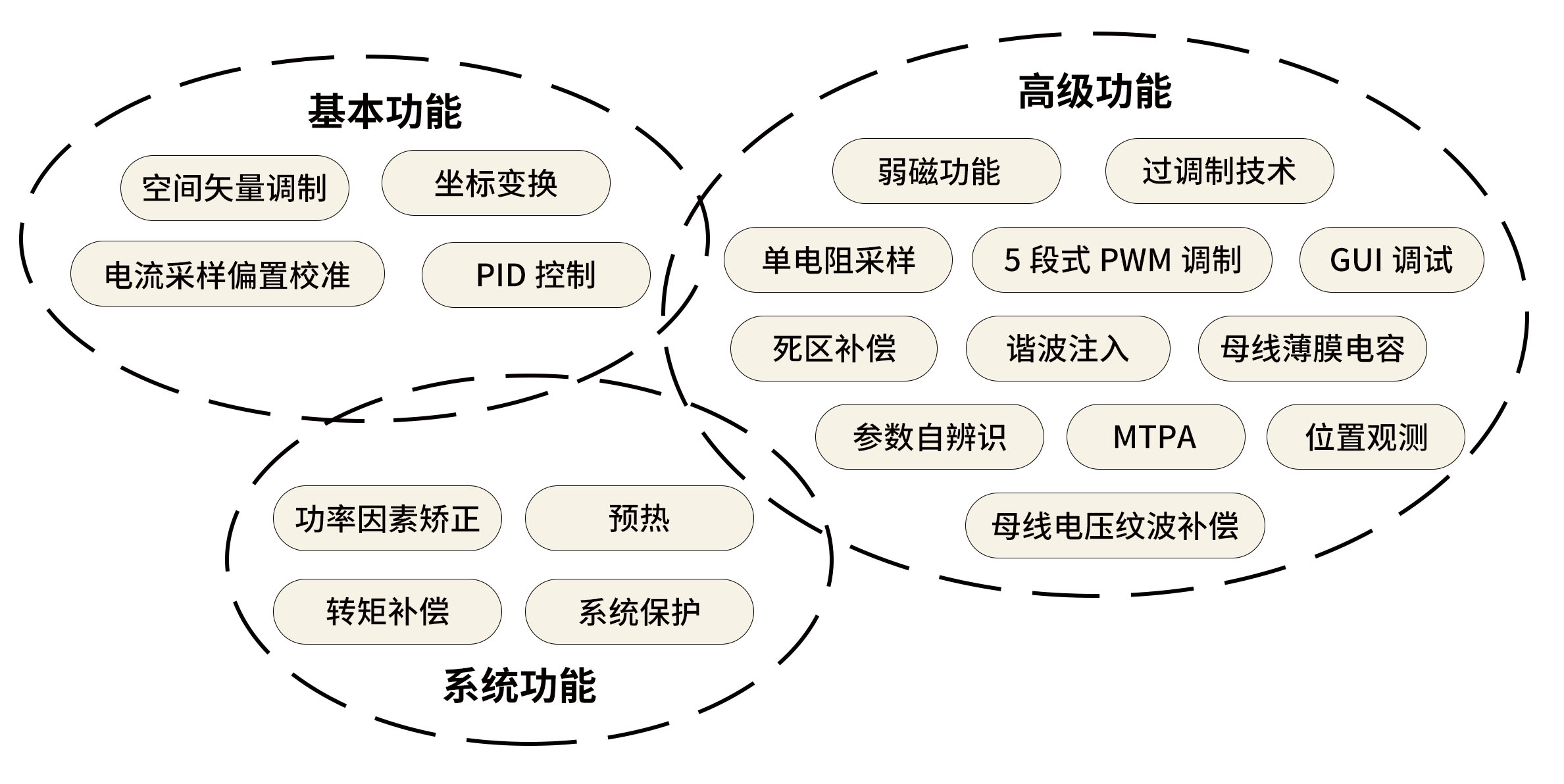

Integration of compressor drive and refrigerator system control, FOC vector control, single resistor sampling, discrete IGBT; power 300W, speed 720~4500 RPM, accuracy 10 RPM.

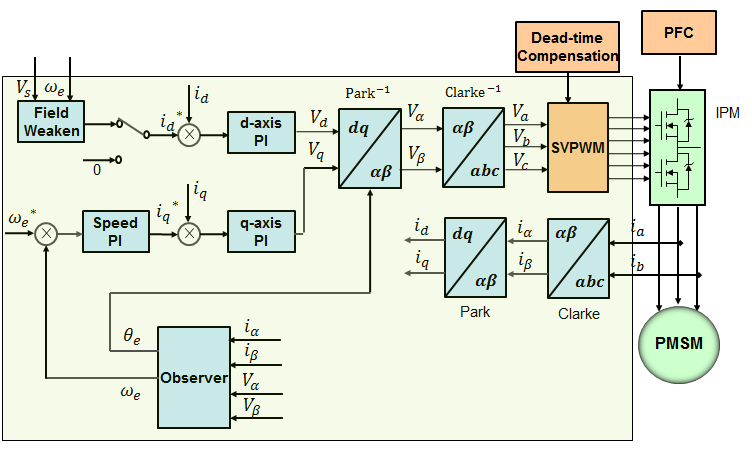

(2) Fan Variable Frequency Drive Controller

FOC vector control, isolated drive, IPM module, bus film capacitor, three-resistor sampling, low-speed high-torque dynamic control, weak magnetic control, torque compensation; power 2KW.

(3)Industrial Agitator Variable Frequency Control

Industrial Agitator, FOC vector control.

No Hall sensors, smooth and stable start.

Fast response, high efficiency.

(4) Dishwasher Pump Driver

FOC vector control, three-resistor sampling, discrete IGBT, built-in or external drive board; power 90W, speed 900~3600 RPM.

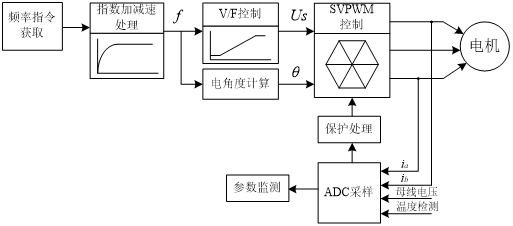

4. AC Induction Motor Speed Control

Space voltage vector algorithm, V/F control, exponential processing for acceleration and deceleration.

5.High-Voltage DC Relay Drive Components

A. Single and Double Coil Relay Drive Components

Wide voltage input, PWM control, constant current drive, timed control, fast shutdown.

B. CSID Relay Drive Components

Large current detection for shunt slices, circuit protection, fast on/off, ASIL C. Can be applied to new energy vehicle battery drive unit BDU, charging piles, and high-reliability applications.

.jpg)

.png)